The Company has a top quality design Manufacturing , Assembly & Quality team with advanced machinery which allows us to handle any critical project at a given timeline.

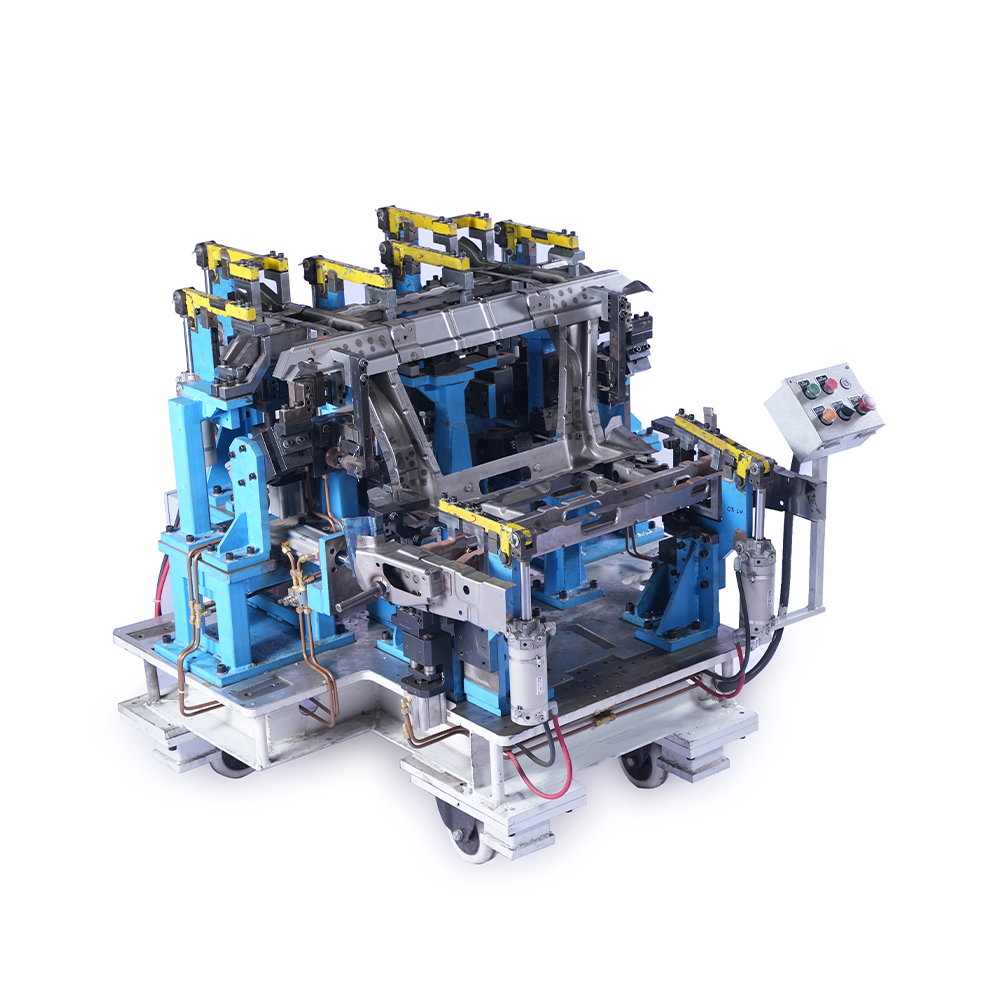

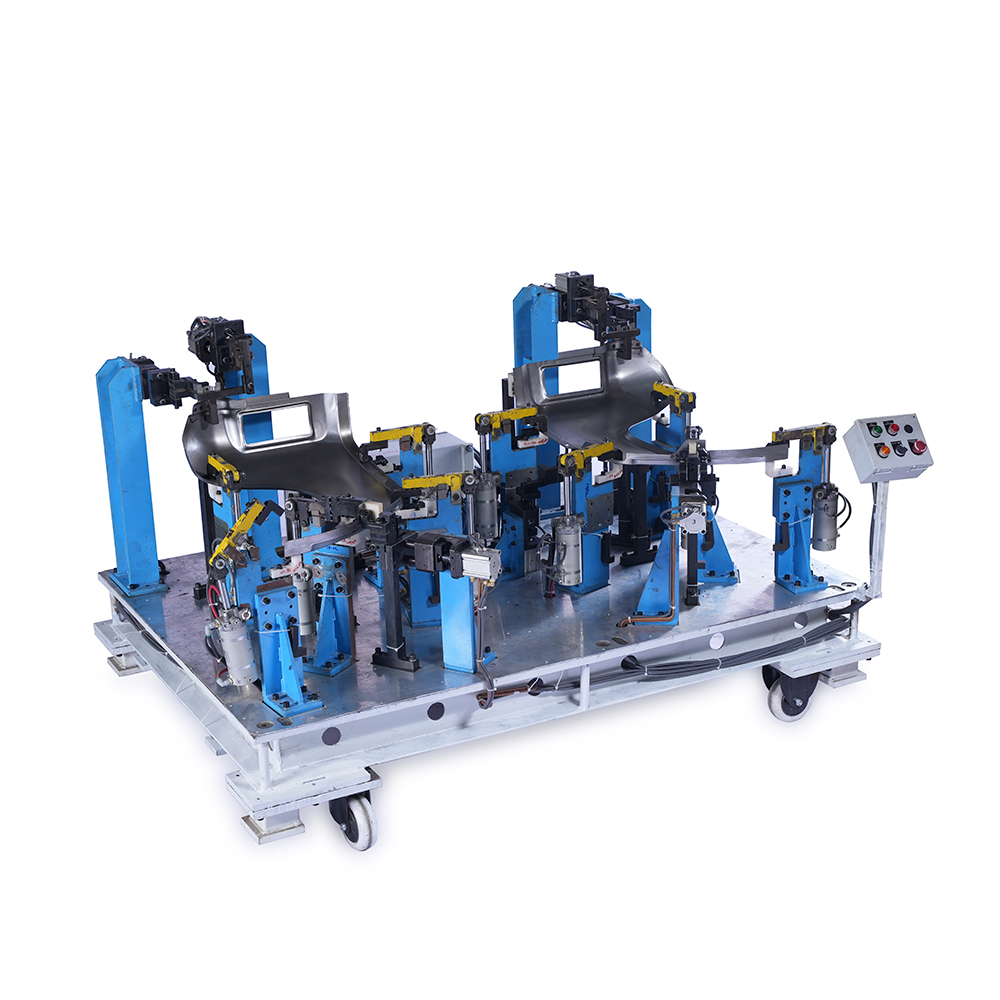

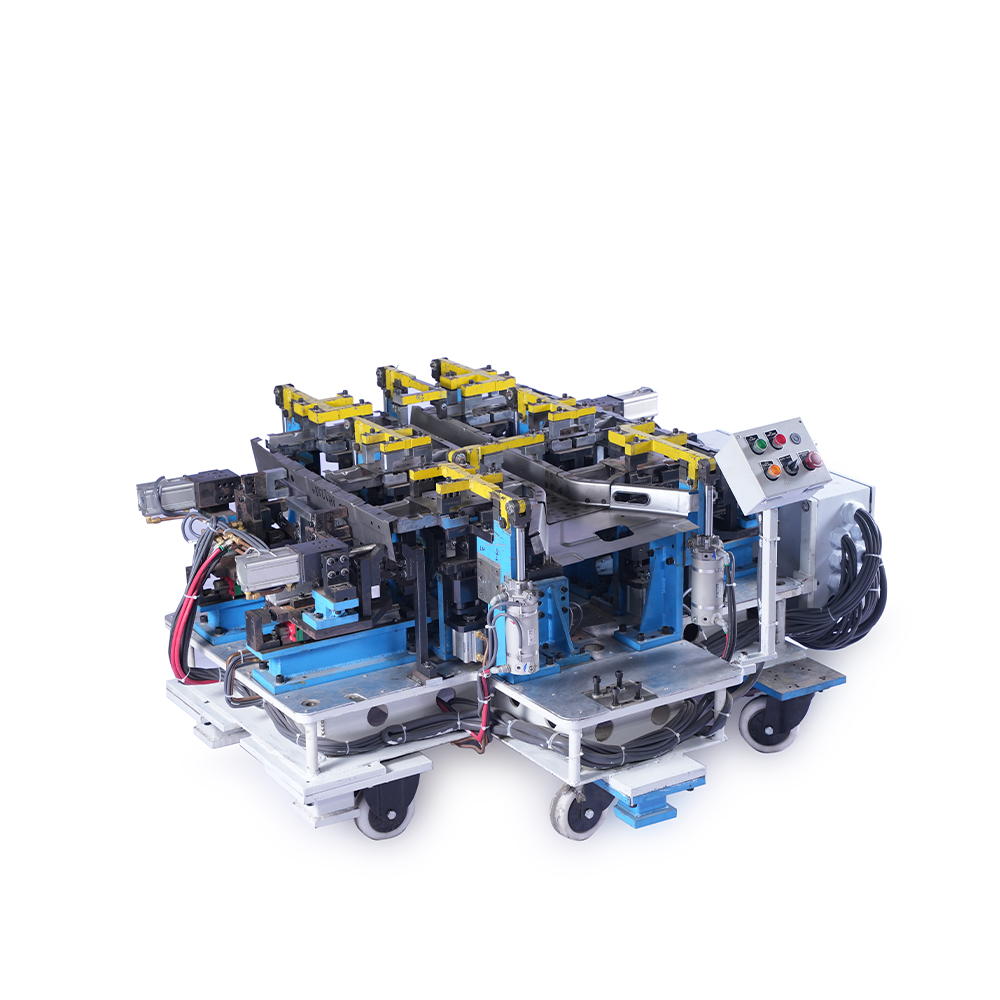

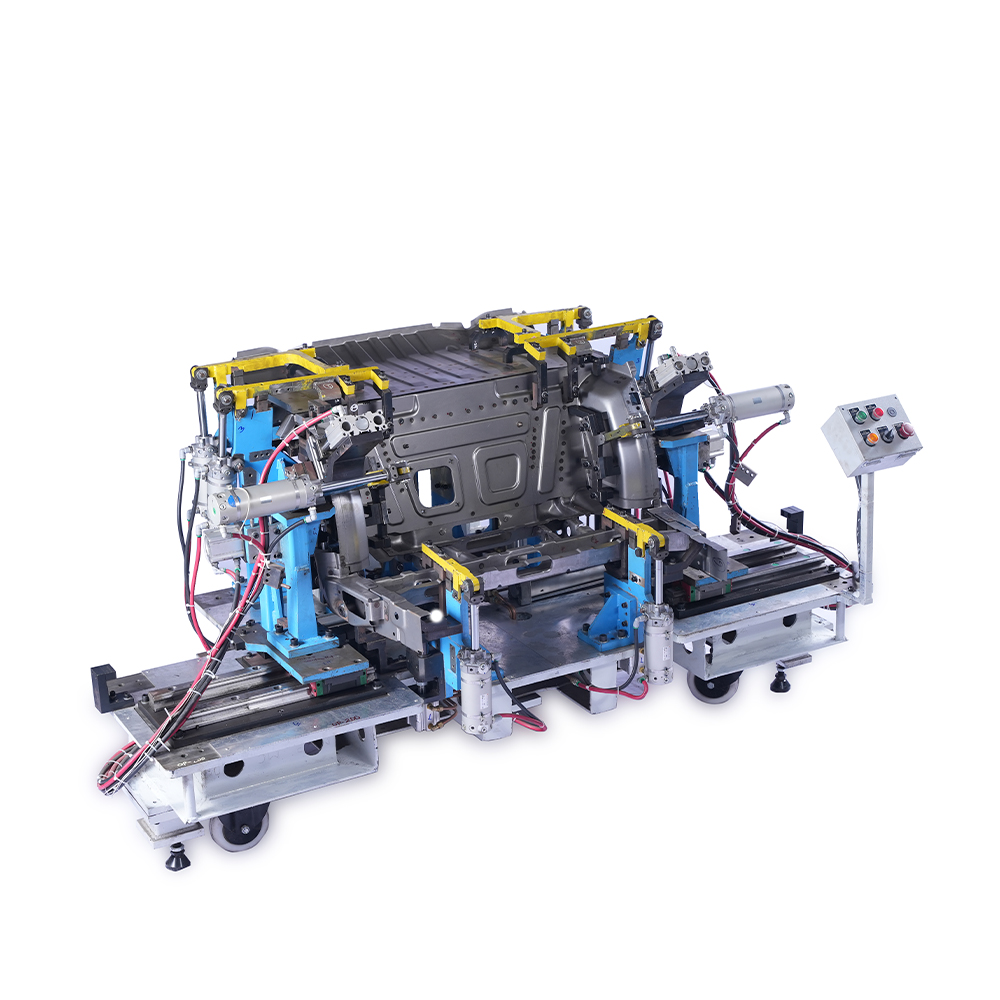

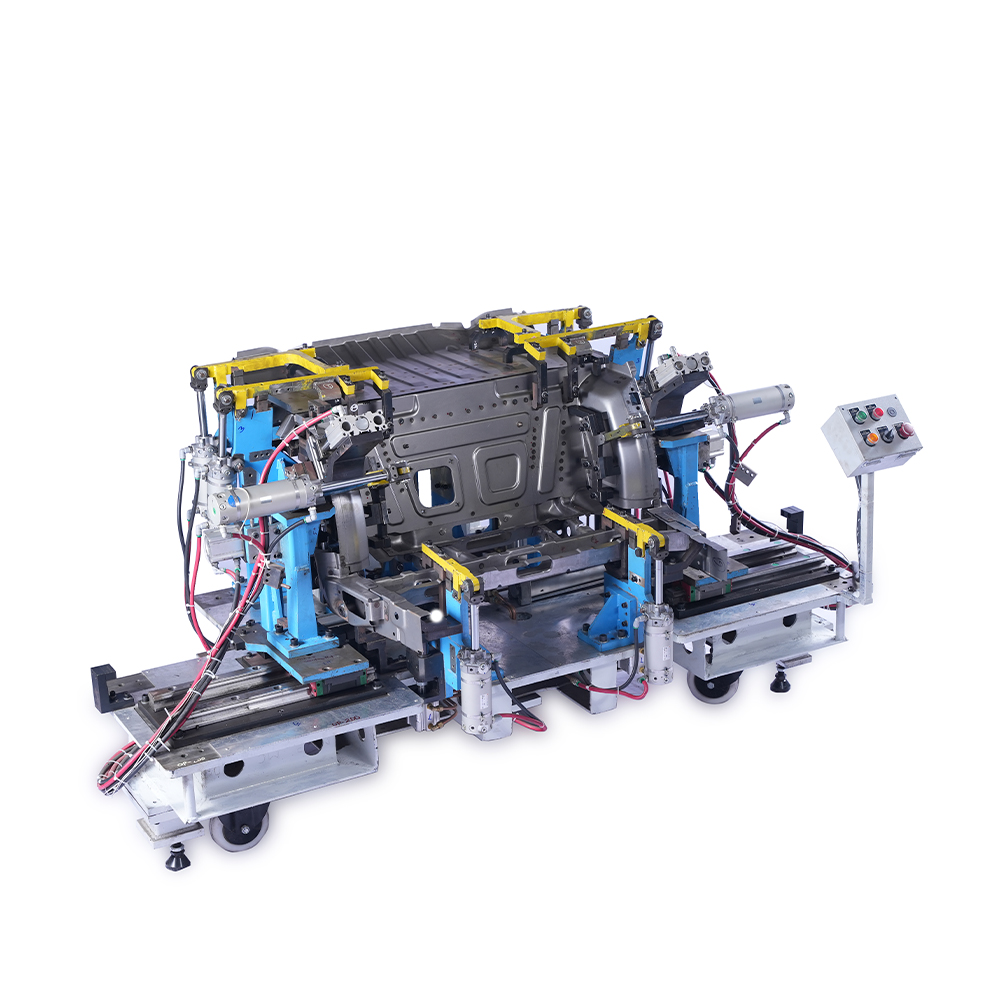

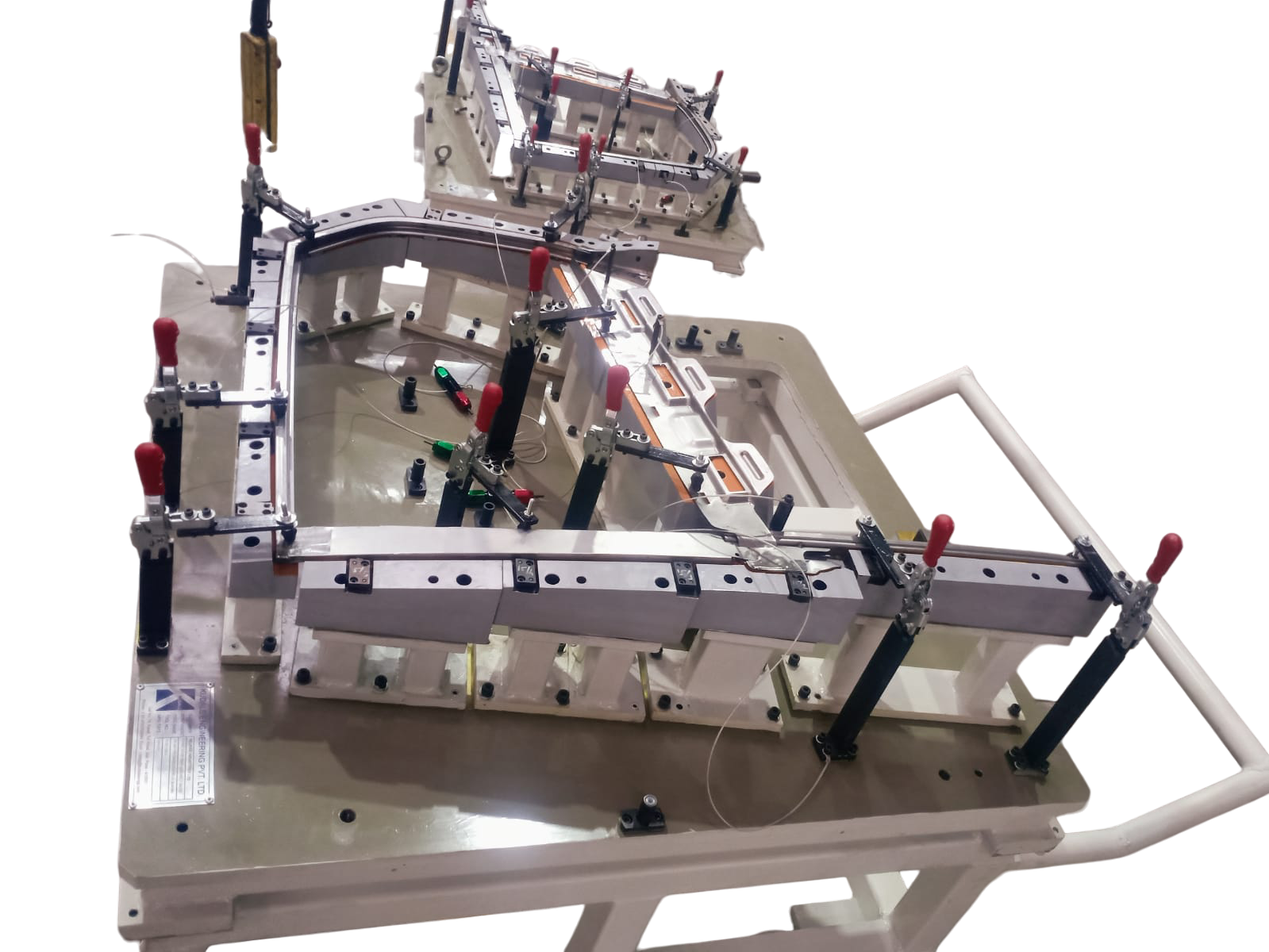

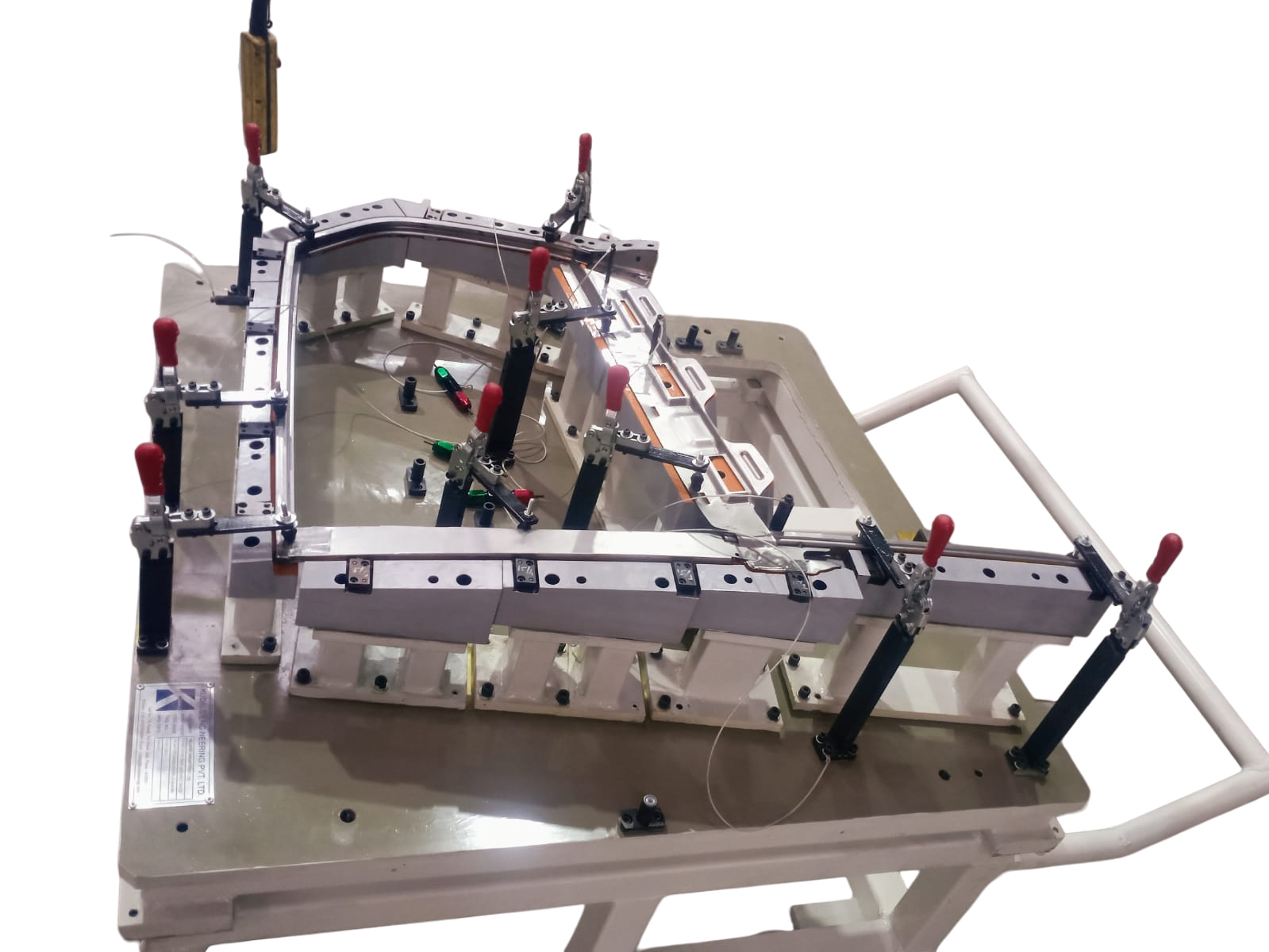

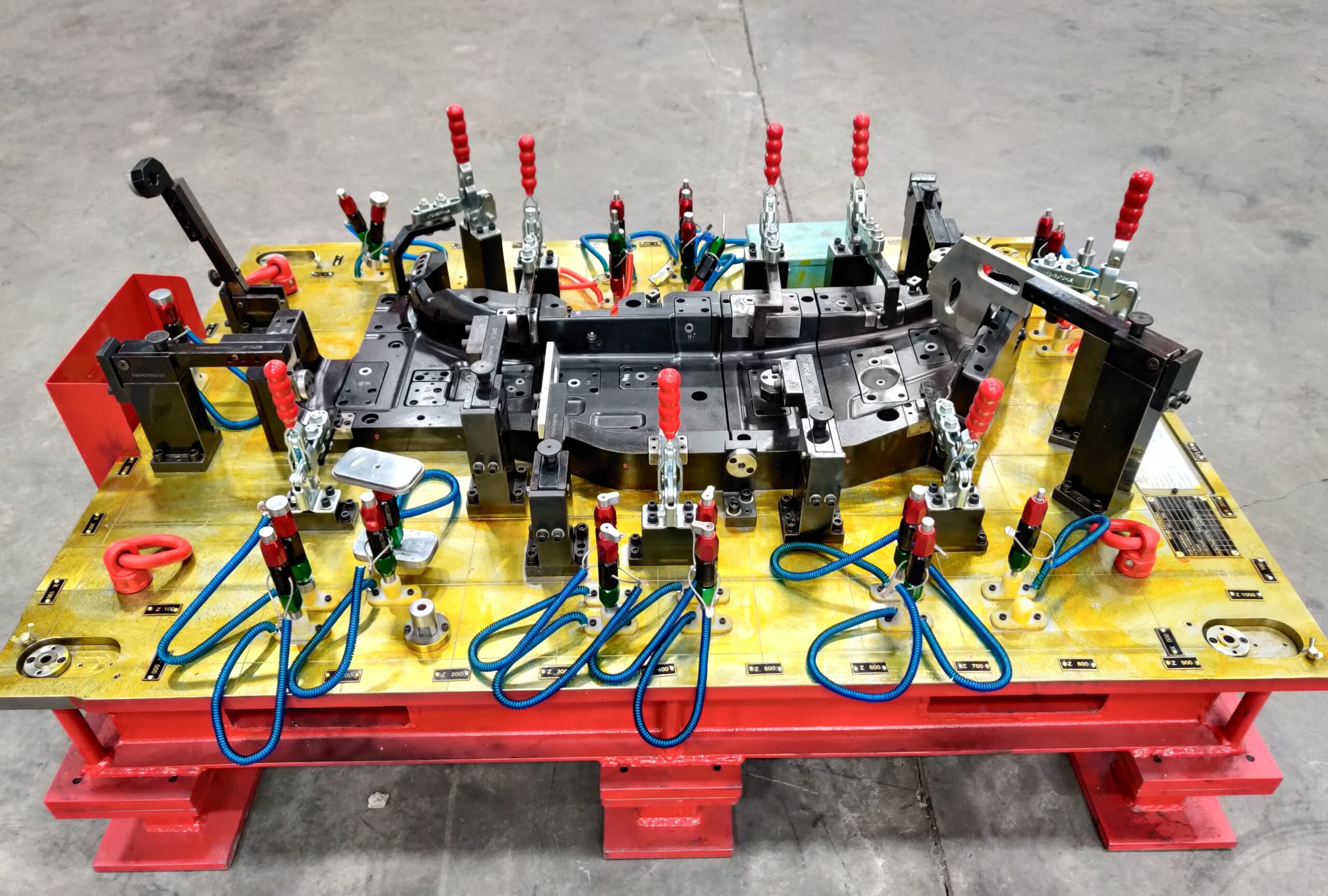

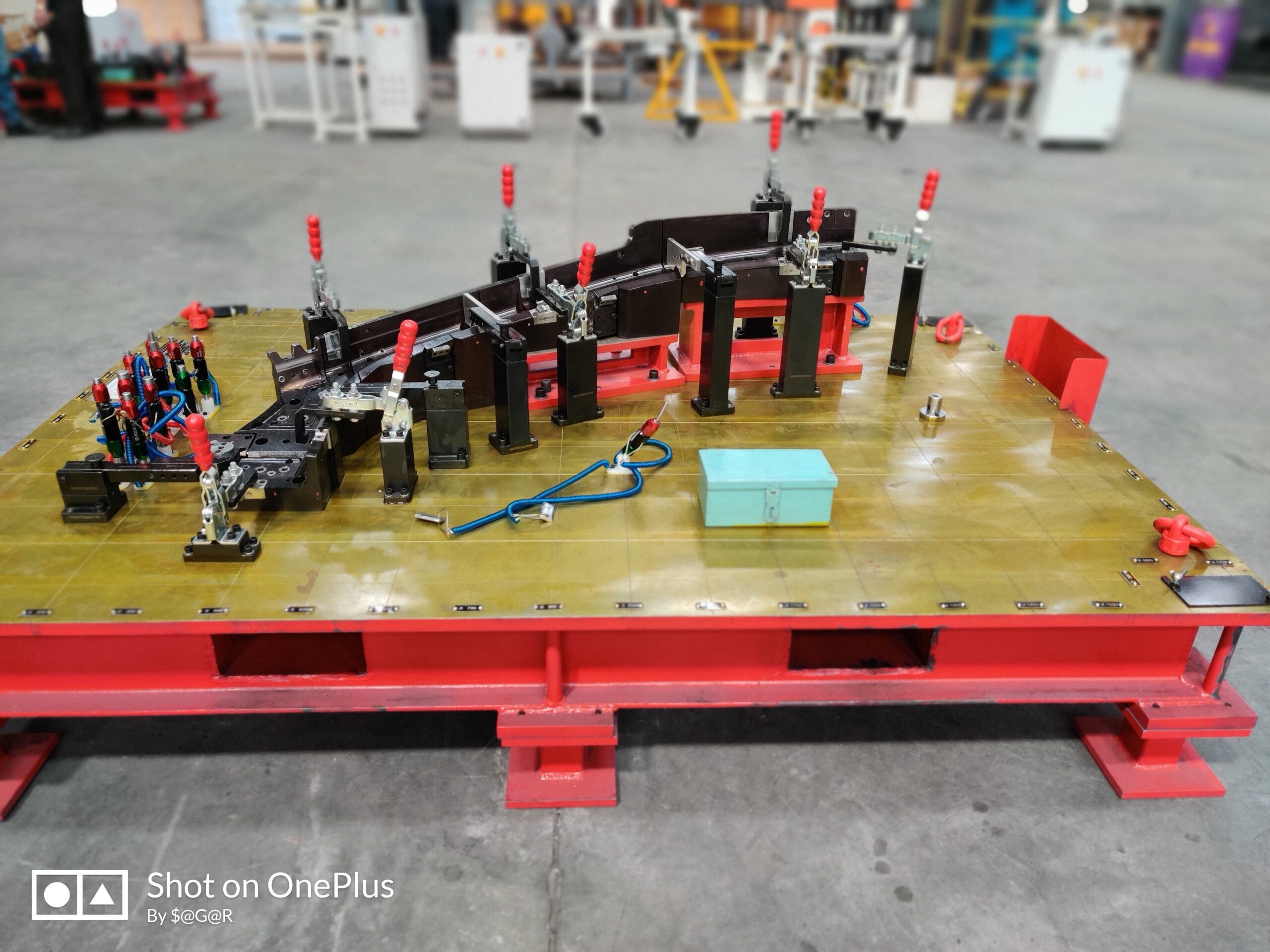

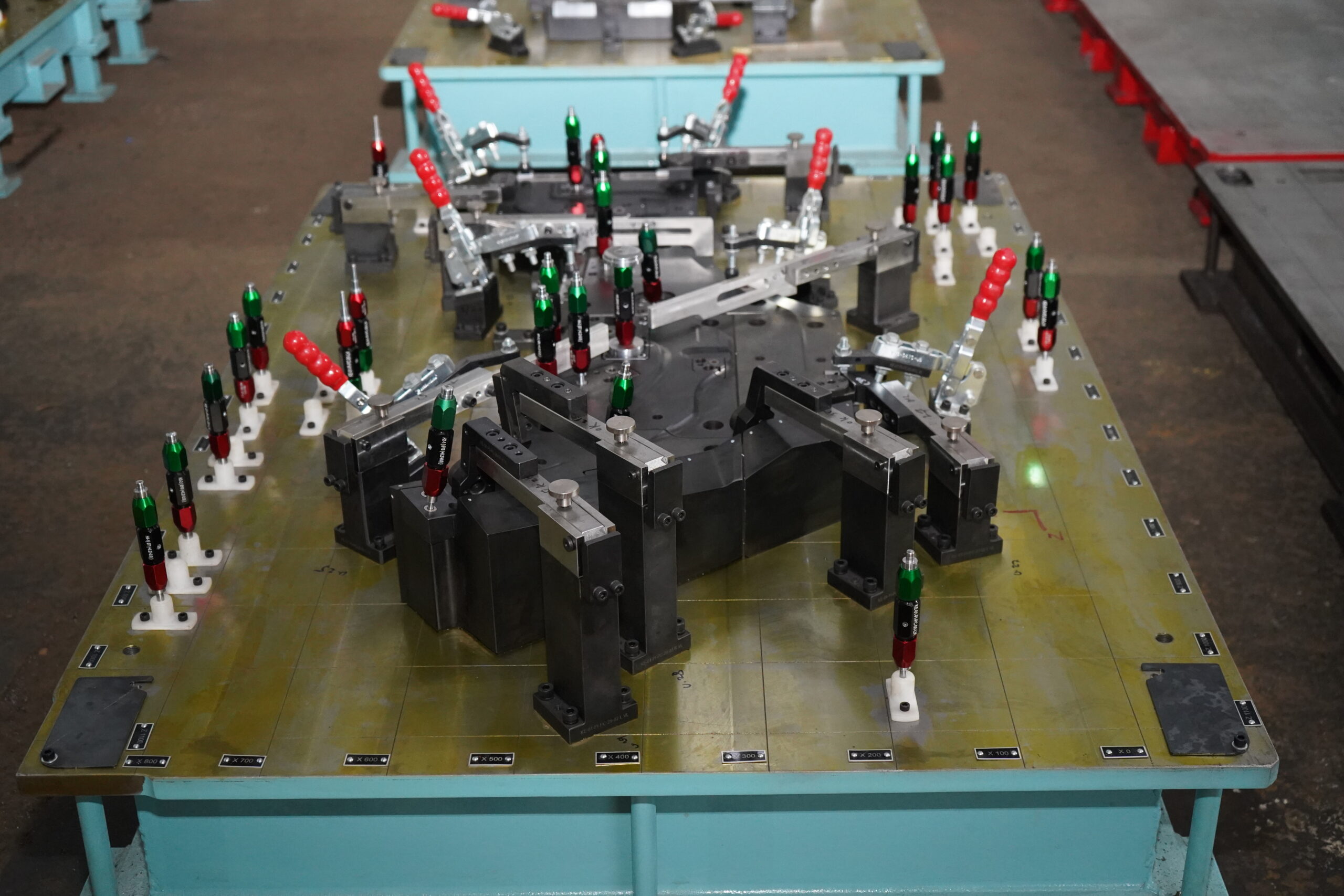

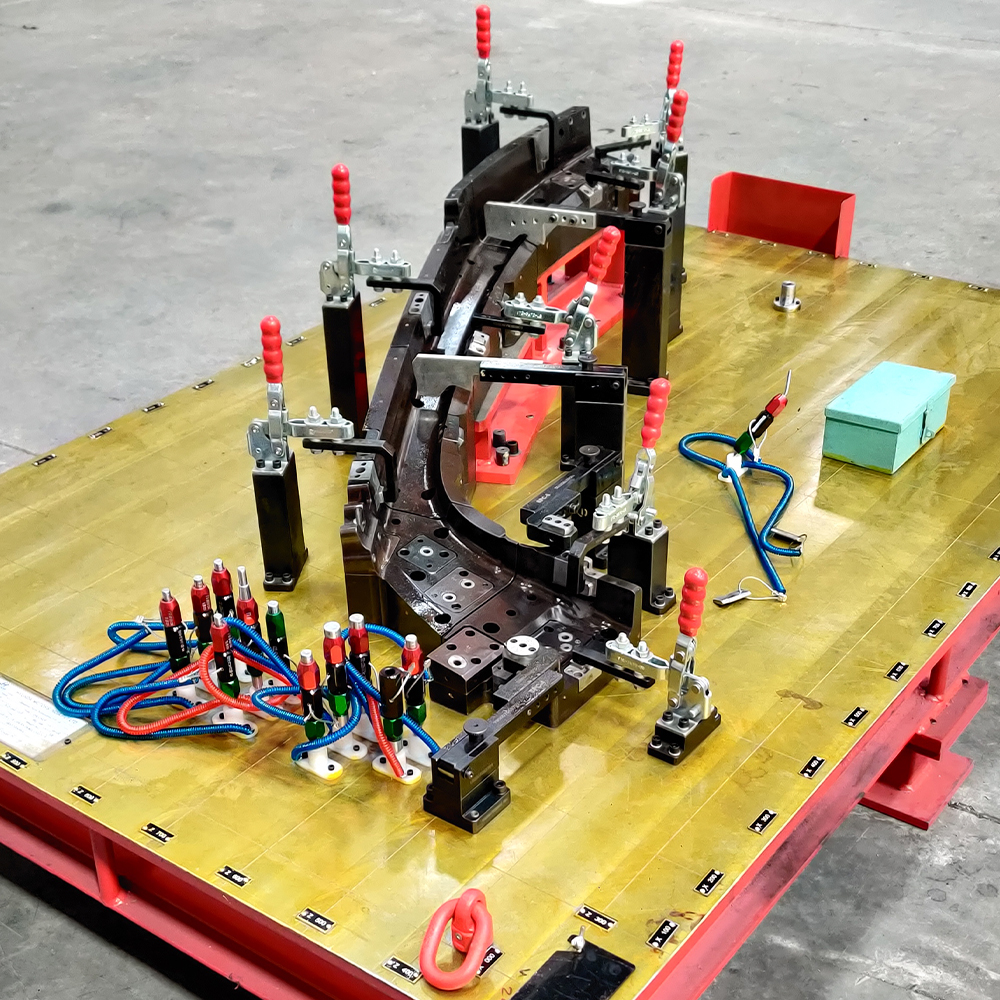

Weld Lines Fixtures Robotics & Manuals

KEPL provides high-precision robotic and manual weld line fixtures for consistent, efficient, and scalable welding solutions across automotive and industrial applications.

Projects delivered for various end customers:

• Bajaj

• Royal Enfield

• HMCL

• TVS

• Kinetic Voults

• Ampere

• Gogoro

• Simple Energy

• Gensol EV

• Zeno Bike

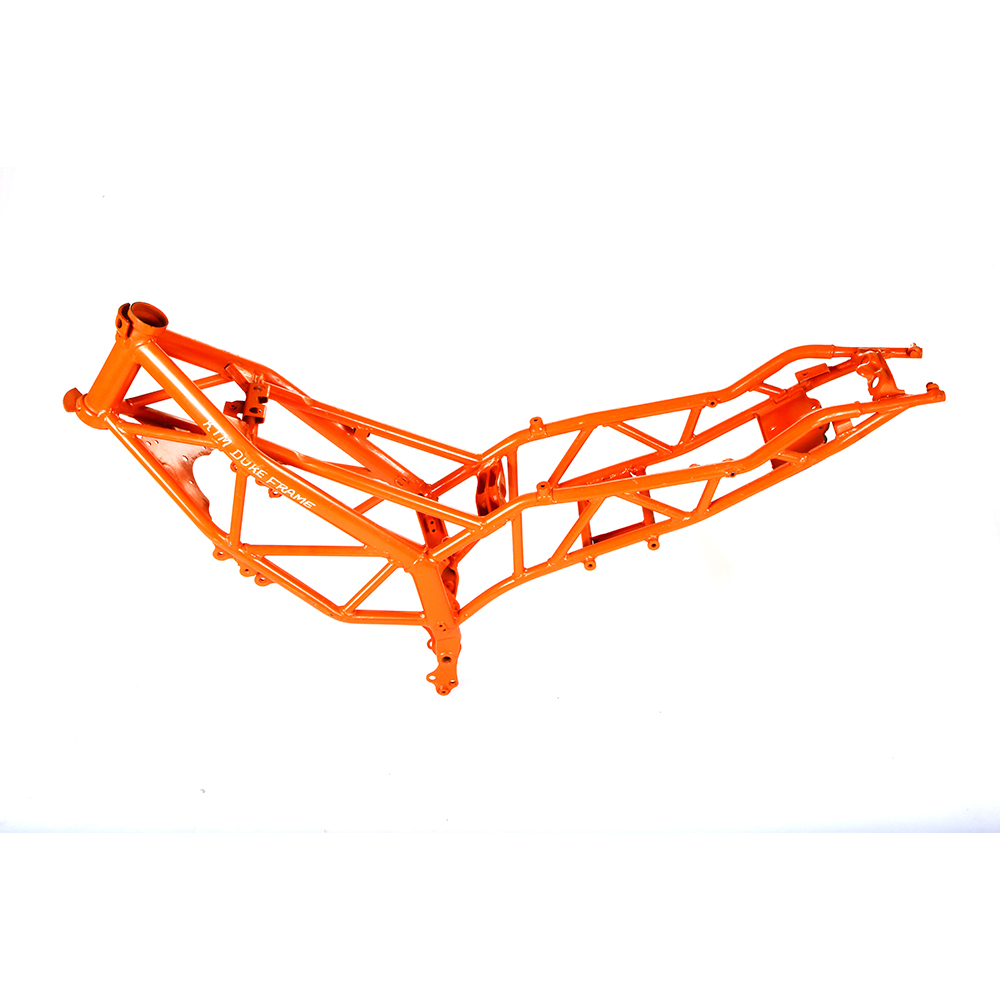

2 Wheelers Project

Designed and delivered precision welding and assembly fixtures for leading two-wheeler manufacturers.

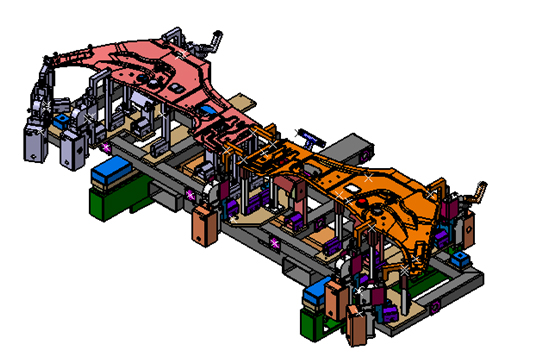

3 Wheelers Project

Developed robust frame line and component fixtures tailored for three-wheeler chassis and body structures.

LINE SCOPE :

• Process

• Welding Simulation

• Fixture Design & Manufacturing

• Assy and Trials

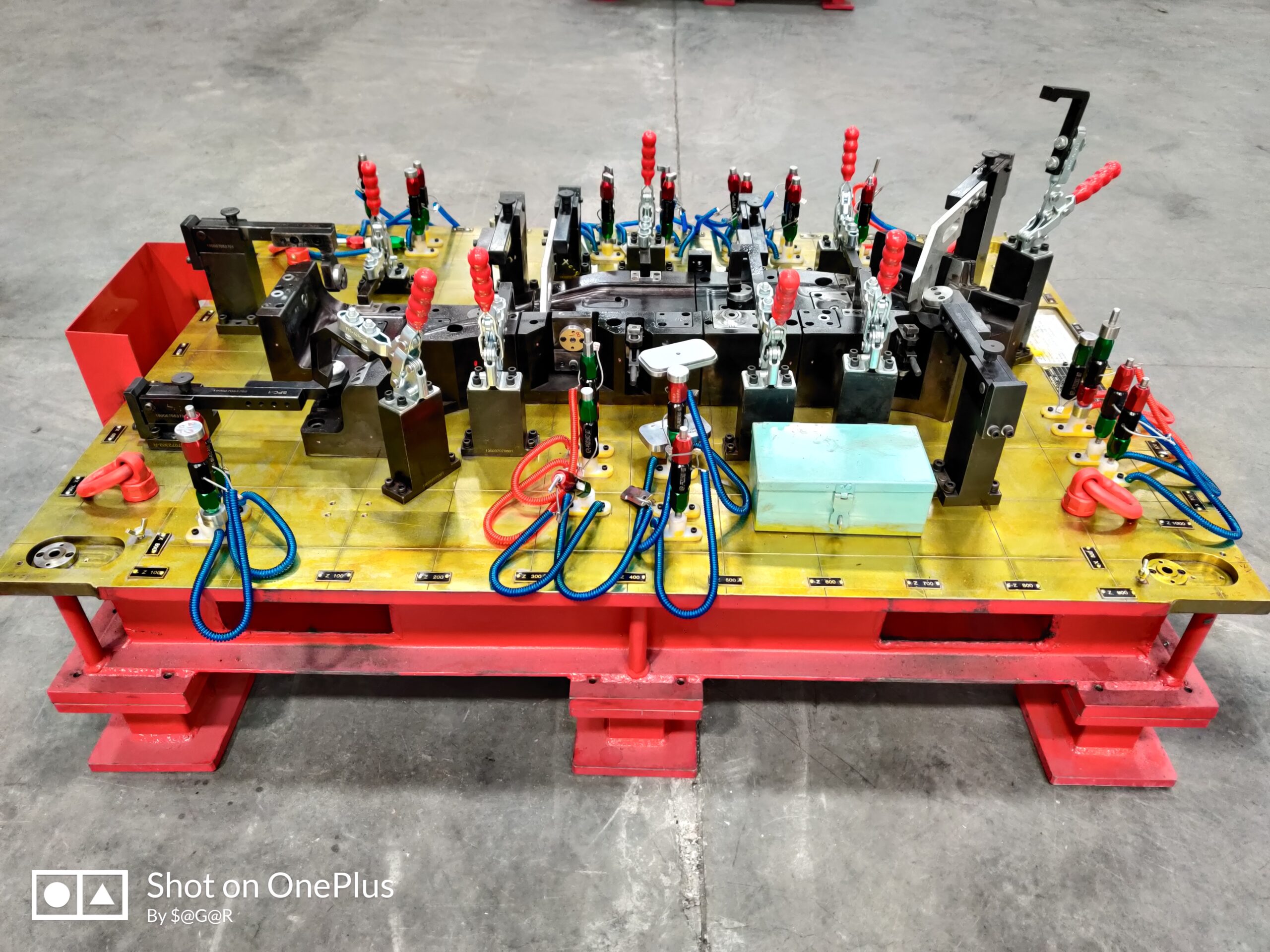

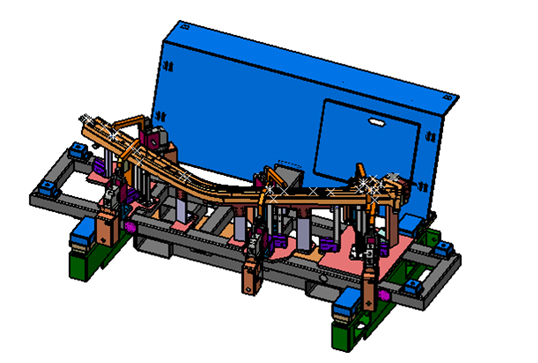

4 Wheelers Project

Supplied high-accuracy BIW and robotic welding fixtures for four-wheeler body assembly lines.

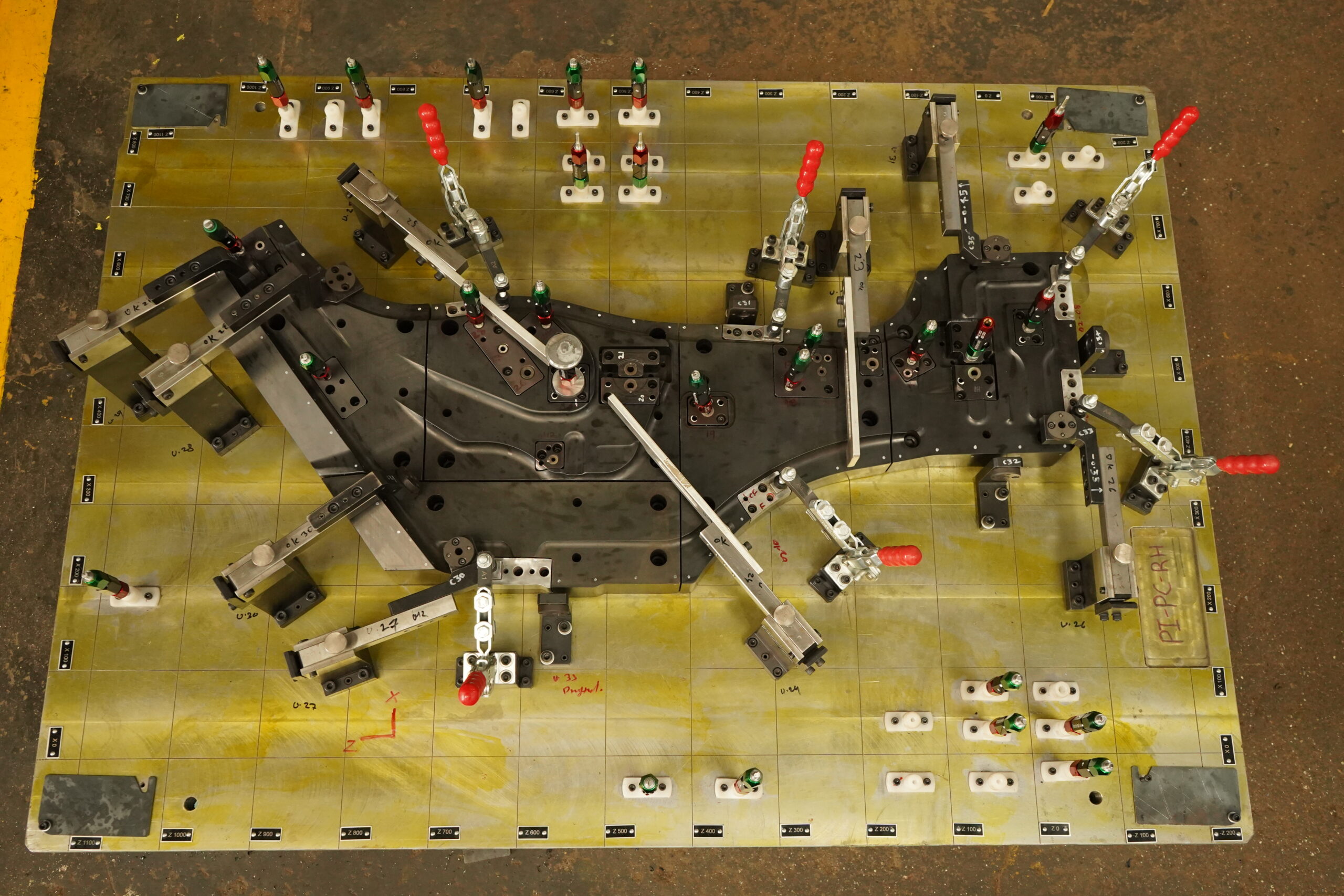

FOR BIW PARTS :

• Checking fixtures

• Spot Welding Fixtures

• CMM Fixtures

• Laser Cutting Fixtures

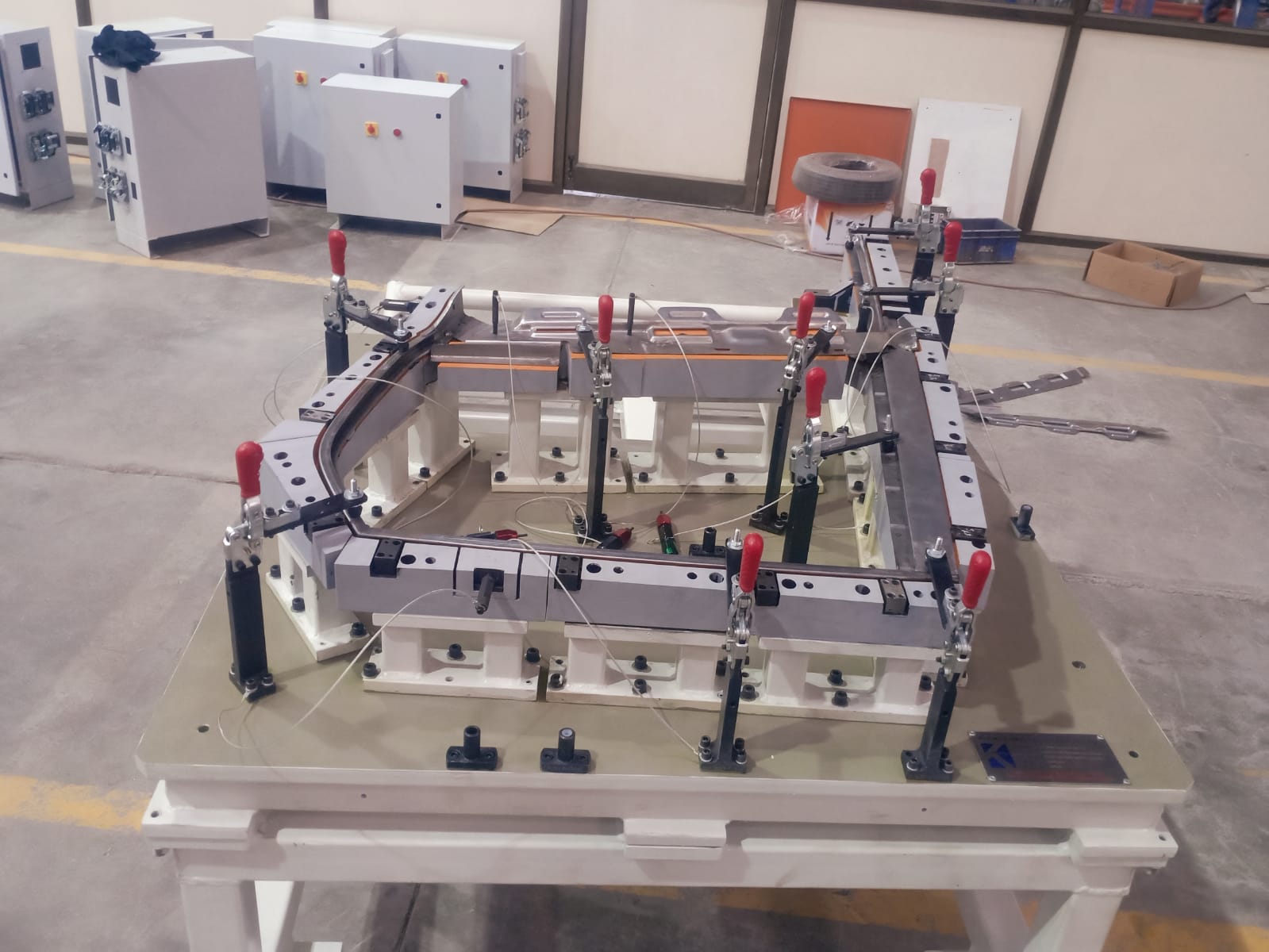

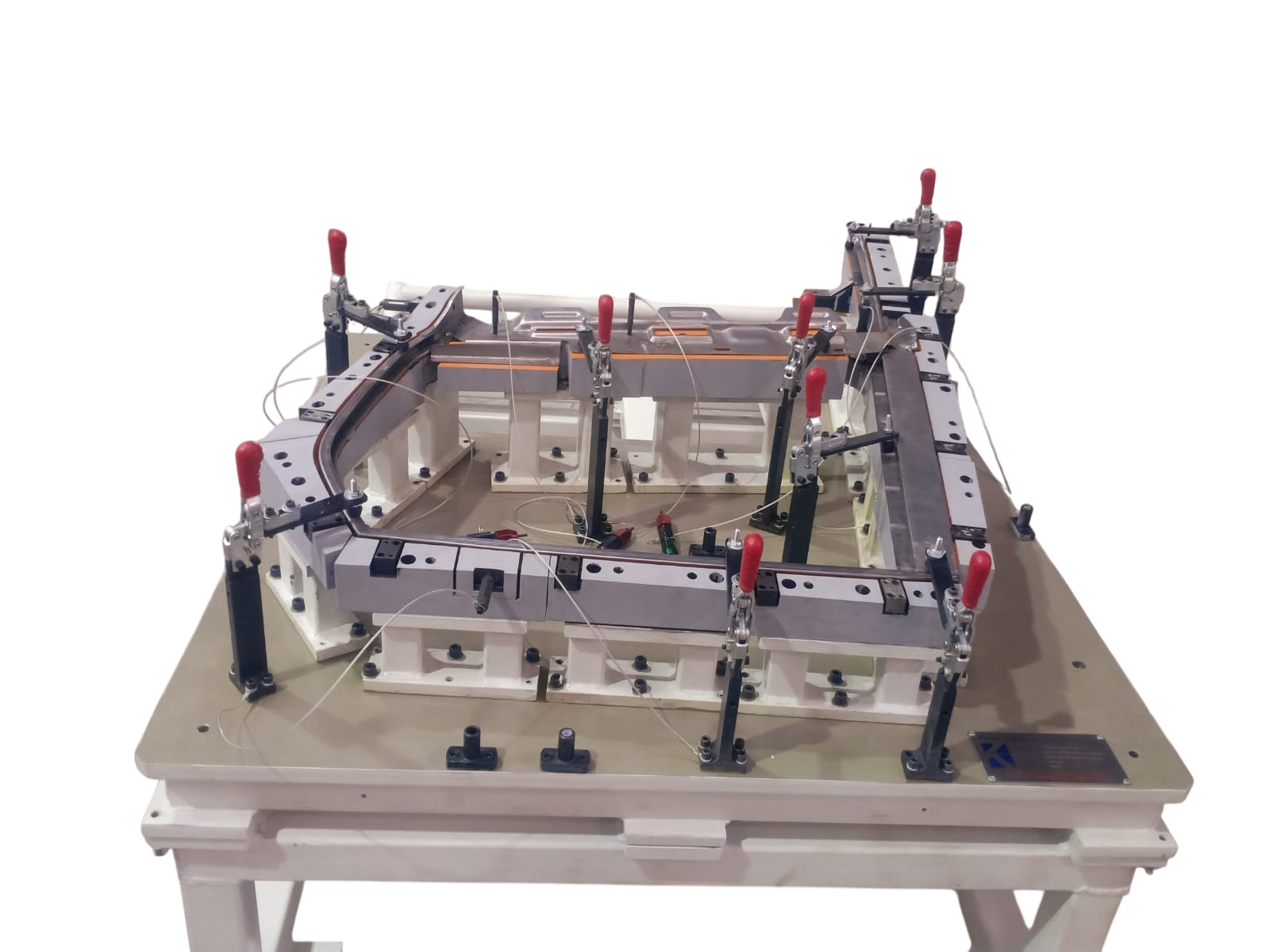

Panel Checking Fixtures

Engineered durable and accurate checking fixtures for critical BIW panel quality validation.

CMM Holding Fixtures

Built custom fixtures to support high-precision CMM inspection for automotive components.

Laser Cutting Fixtures

Provided specialized laser cutting fixtures to ensure consistency and safety in metal trimming operations.

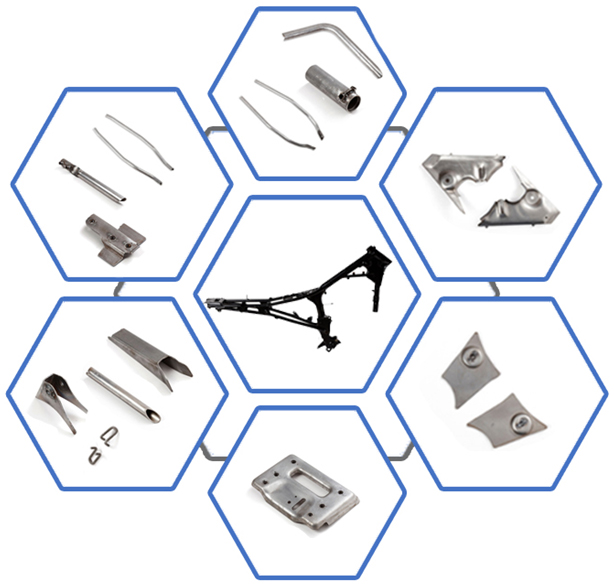

Proto type Development

Executed end-to-end prototype development for new model launches across EV and automotive segments.

LINE CONTENT :

• Process Design

• Child Part development

• Proto Welding Fixtures

• Frame CMM & 3D Scanning

• Weld Penetration

• Frame ED Coating