Advantages

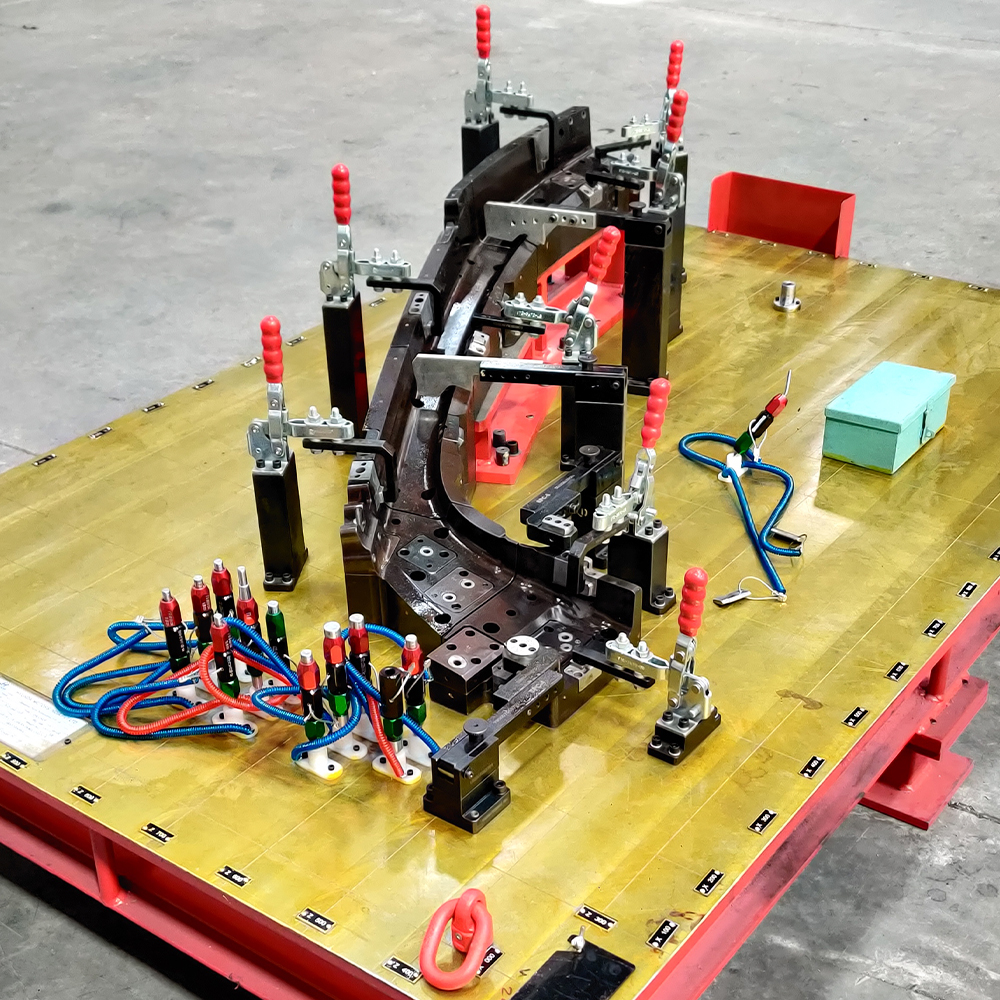

Fully equipped in-house setup with skilled team, CMM with Delcam, turnkey project capability, and strong focus on timely delivery

Core Values

Live to Give | Value in Relationships | Commit & Deliver | Building Trust

Strength

20+ years of expertise in turnkey welding automation and checking solutions, with in-house design, fast execution, and trusted by top OEMs.

About Us

Founded in 2000, Kudale Engineering Pvt. Ltd. has evolved into a trusted partner for automotive, EV and general engineering sectors. We specialize in welding automation, BIW fixtures, SPMs and advanced manufacturing systems based in Pune, Maharashtra.

We deliver solutions that enhance automation, precision, and efficiency for the automotive, EV, and other industrial sectors. Our expertise spans Assembly Line Automation, Robotic Welding Lines (MIG, TIG, Spot), Welding Fixtures, Checking Gauges, and Special Purpose Machines (SPM). We also offer IoT-enabled Industry 4.0 solutions for smart manufacturing.

SE & Consulting

Process Planning

Tooling Design

Robotic Simulation

Layout Optimization

Manufacturing Parts / Bought outs & Assembly

Inspection

Panel Fitment

Installation commissioning, JPH proving & rampup support

PLC and Robotic programming, Tryout/Cycle Time, proveout and quality

- Experience of complete Body shop Process planning from Mainlines to Final Assembly lines.

- Product Feasibility Analysis, Station wise Product Flow planning.

- Cycle Time Analysis, Block Layout planning.

- Weld Gun, Robot & Other Bought out Equipment's preliminary selection.

- Operator Ergonomic analysis, Safety planning, Material handling.

- Bill of material (Tools & Bought out Equipment’s).

- Spot welding, MIG welding, Bolting, Riveting, Gluing, Nut clinching & Projection welding.

- Robotic Simulation with vast experience of project execution for leading

- Auto manufacturers

- Work cell Set Up, Process, Layout Validation & Optimization.

- Weld Spot/MIG/Sealing Distribution.

- Weld Gun Selection, Robot reach-ability study, Robot Selection.

- Tool Validation & Identify Potential Issues.

- Sequence Of Operation, Cycle Time Optimization.

- Robot-safe operation. Safe working zone defining.

- Spot Welding, Riveting, MIG welding, Sealant Application, Stud Welding & Hemming.

- Managing design projects of Manual Welding lines, robotic welding lines,

- Automated assembly lines, material handling.

- Welding Fixtures, Gripper, Setting Jig & Inspection Jig.

- Weld Gun Selection, Robot Payload Validation.

- Operator Ergonomic analysis & Validation.

- 2D drawings, Bill of Material.

- Pneumatic Sequence sheets

- Final Process documents like Process flow chart, Clamping plan,

- Weld distribution, Weld Matrix, Ergonomic validation.

- Assembly, Manufacturing & Installation Site support.

Why Choose Us

The Company has a top quality design,

Manufacturing , Assembly & Quality team with advanced machinery which allows us to handle any critical project at a given timeline.

Complete design & manufacturing set up with skilled man power & excellent machinery.

In House Complete Machine shop set up, In House stationary CMM (2 m x 1.2 m x 1.0 m) with Delcam software.

Always committed towards customers in time requirement.

Discover innovative projects driving the future of automation.

We proudly support a diverse range of industries with tailored solutions that meet their unique challenges.

Testimonials

Discover how our services have made a difference for businesses and individuals alike. Here’s what our satisfied clients have to say.

Tell us about your project or needs, and we’ll provide a customized quote tailored to your requirements—quick, easy, and obligation-free.

Latest Update

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!